China Wholesaler of Truck Engine PTO Power Distribution Gearboxes

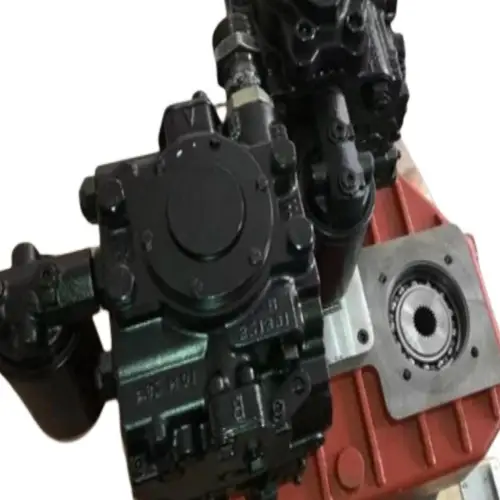

Our hydraulic pump drives or hydraulic pump gearbox is the perfect solution for converting mechanical power to hydraulic power, making it ideal for both stationary and mobile applications. These gearboxes are used to connect a prime mover like an internal combustion engine or an electric motor to one or more hydraulic pumps.

Our hydraulic pump drives are designed to save space, reduce weight, and eliminate the number of components needed in machinery. With our modular pump drives, you can drive 2 to 4 pumps simultaneously, providing design flexibility and boosting system efficiency.

Hydraulic Pumps Drives Gearboxes: Features and Benefits

Our hydraulic pumps drives gearboxes consist of a gear drive inside a CHINAMFG housing that connects to a gasoline or diesel engine. The opposite side contains 1 or more standard 2- or 4-bolt flanges for mounting hydraulic pumps. This configuration provides several benefits.

- Connects 2 or more identical pumps to provide nearly identical hydraulic output flow from each.

- Use different sized pumps to provide output flow proportional to the displacement of each pump.

- Saves space and weight

- Eliminates the number of components needed in machinery

- Reduces assembly time for the whole machinery

Our hydraulic pump drives gearbox can handle a maximum input power of up to 700KW and a maximum output torque of up to 1900Nm per pump pad. It can also handle a maximum input speed of up to 2800 RPM and a maximum output speed of up to 3200 RPM. The transmission ratio ranges from 0.67 to 0.98, depending on the model.

Hydraulic Pump Drives Gearboxes: Specifications

| Model | 2 pumps drive | 3 pumps drive | 4 pumps drive | |||||||

| Parameter | KK190-2N | KK400-2N | KK530-2N | KK700-2N | KK280-3N | KK400-3N | KK530-3N | KK700-3N | KK530-4N | KK700-4N |

| Max. Input power (KW) | 190 | 400 | 530 | 700 | 280 | 400 | 530 | 700 | 530 | 700 |

| Max. Output power per pump pad (KW) | 110 | 210 | 270 | 360 | 150 | 210 | 270 | 360 | 270 | 330 |

| Max. Output torque per pump pad (Nm) | 400 | 900 | 1500 | 1900 | 800 | 900 | 1500 | 1900 | 1500 | 1800 |

| Max. Input speed (RPM) | 2800 | 2600 | 2600 | 2400 | 2800 | 2600 | 2600 | 2400 | 2600 | 2400 |

| Max. Output speed (RPM) | 3200 | 2800 | 2800 | 2700 | 3200 | 2800 | 2800 | 2700 | 2800 | 2700 |

| Transmission ratio | 0.74/0.81/0.89/0.98… | 0.67/0.74/0.81/0.89/0.98… | 0.67/0.74/0.81/0.89/0.98… | 0.67/0.74/0.81/0.89/0.98… | 0.74/0.81/0.89/0.98… | 0.67/0.74/0.81/0.89/0.98… | 0.67/0.74/0.81/0.89/0.98… | 0.67/0.74/0.81/0.89/0.98… | 0.67/0.74/0.81/0.89/0.98… | 0.67/0.74/0.81/0.89/0.98… |

| Mount size of Prime mover | SAE #3 #4 etc. | SAE #2 #3 etc. | SAE #1 #2 #3 etc. | SAE #0 #1 #2 etc. | SAE #3 #4 etc. | SAE #2 #3 etc. | SAE #1 #2 #3 etc. | SAE #0 #1 #2 etc. | SAE #1 #2 #3 etc. | SAE #1 #2 etc. |

| Port size of Single pump | SAE A,B,C flange etc. | SAE A,B,C,D flange etc. | SAE B,C,D,E flange etc. | SAE C,D,E flange etc. | SAE A,B,C flange etc. | SAE A,B,C,D flange etc. | SAE B,C,D,E flange etc. | SAE C,D,E flange etc. | SAE B,C,D,E flange etc. | SAE B C,D flange etc. |

| Housing material | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron |

Other Industrial Products Offered

Aside from hydraulic pump drives gearbox, our company also supplies a wide range of products for industrial use. Our products include agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, and bushings. We take pride in offering high-quality products, preferential prices, and considerate services. We also welcome customers to customize drawings and samples to meet their specific needs.

FAQs

What is a hydraulic pump drives gearbox?

A hydraulic pump drives gearbox is the perfect solution for converting mechanical power to hydraulic power. It is used to connect a prime mover like an internal combustion engine or an electric motor to one or more hydraulic pumps.

What are the benefits of using hydraulic pump drives gearbox?

Hydraulic pump drives gearbox saves space and reduces weight. It also eliminates the number of components needed in machinery and reduces assembly time for the whole machinery.

What is the maximum input power and maximum output torque per pump pad of hydraulic pump drives gearbox?

The maximum input power of hydraulic pump drives gearbox is up to 700KW and the maximum output torque per pump pad is up to 1900Nm.

What is the maximum input speed and output speed of hydraulic pump drives gearbox?

The maximum input speed of hydraulic pump drives gearbox is up to 2800 RPM and the maximum output speed is up to 3200 RPM.

What other products does your company offer?

Aside from hydraulic pump drives gearbox, our company also supplies agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, and bushings. We take pride in offering high-quality products, preferential prices, and considerate services. We also welcome customers to customize drawings and samples to meet their specific needs.

Disclaimer: All content on this page is sourced from the Internet and is provided solely as a reference for product selection. Our products are replacement parts and not original spare parts. We do not claim ownership of the original trademarks mentioned in the content. Our replacement parts are designed to perfectly adapt to the original spare parts. For the purchase of original spare parts, please contact the original factory or supplier.

Introduction to the Performance Characteristics of Pto Gearbox

The Pto gearbox is known for its exceptional performance characteristics. Let’s delve into its key features:

1. High Efficiency: The Pto gearbox is designed to optimize power transmission, ensuring maximum efficiency and minimal energy loss.

2. Robust Construction: With its durable build, the Pto gearbox can withstand heavy loads and harsh operating conditions, making it suitable for various applications.

3. Smooth Operation: Thanks to its precise engineering and high-quality components, the Pto gearbox offers smooth and reliable operation, reducing noise and vibration.

4. Versatility: The Pto gearbox can be easily adapted to different machinery and equipment, making it a versatile choice for various industries.

Types and Characteristics of Pto Gearbox

Pto gearboxes come in different types, each with its own unique characteristics. Let’s explore them:

1. Bevel Gear Pto Gearbox: This type of gearbox is known for its compact design and high torque capacity, making it ideal for applications that require heavy-duty performance.

2. Worm Gear Pto Gearbox: With its high gear ratio and self-locking feature, the worm gear Pto gearbox offers excellent stability and precise control.

3. Planetary Gear Pto Gearbox: This gearbox type provides high torque output, smooth operation, and efficient power transmission, making it suitable for demanding applications.

Advantages of Pto Gearbox made of Different Materials

The choice of materials for Pto gearboxes can greatly impact their performance. Let’s explore the advantages of different materials:

1. Steel Pto Gearbox: Known for its excellent strength and durability, steel gearboxes offer exceptional resistance to wear and tear, ensuring a longer lifespan.

2. Aluminum Pto Gearbox: Aluminum gearboxes are lightweight and provide good heat dissipation, making them suitable for applications that require reduced weight and efficient cooling.

3. Cast Iron Pto Gearbox: Cast iron gearboxes are renowned for their exceptional durability and resistance to shock and impact, making them suitable for rugged environments.

Application of Pto Gearbox in Various Fields

The Pto gearbox finds extensive use in diverse industries. Let’s explore its application in various fields:

1. Agricultural Machinery: Pto gearboxes play a crucial role in agricultural machinery, facilitating power transmission for tasks such as crop harvesting, plowing, and irrigation.

2. Construction Equipment: Pto gearboxes are essential components in construction equipment, enabling efficient power transfer for tasks like earthmoving, concrete mixing, and lifting.

3. Forestry Equipment: Pto gearboxes are vital in forestry equipment, powering wood processing, logging, and tree felling operations with precision and reliability.

4. Marine Applications: Pto gearboxes are utilized in marine applications, enabling power transmission for marine propulsion systems, winches, and other equipment onboard vessels.

5. Industrial Machinery: Pto gearboxes are employed in various industrial machinery, including conveyor systems, manufacturing equipment, and material handling systems.

Future Development Trends and Opportunities

The Pto gearbox market shows promising trends and opportunities for growth. Some key areas of development and potential prospects include:

1. Advancements in Technology: With ongoing technological advancements, Pto gearboxes are expected to become more efficient, compact, and capable of handling higher torque loads.

2. Integration with IoT: The integration of Pto gearboxes with the Internet of Things (IoT) technology holds potential for enhanced monitoring, predictive maintenance, and improved performance optimization.

3. Sustainable Solutions: As environmental consciousness grows, there is a rising demand for Pto gearboxes that prioritize energy efficiency, reduced emissions, and sustainable manufacturing practices.

4. Emerging Markets: The expanding industrial sectors in developing economies present opportunities for the Pto gearbox market to expand its reach and cater to diverse applications.

Choosing a Suitable Pto Gearbox

Selecting the right Pto gearbox requires careful consideration of several aspects:

1. Load Requirements: Analyze the torque and power requirements of your application to ensure the Pto gearbox can handle the expected loads effectively.

2. Ratio Selection: Determine the desired gear ratio based on the specific operational needs of your machinery or equipment.

3. Type of Gearbox: Consider the advantages and limitations of different Pto gearbox types (bevel, worm, planetary) to choose the one that best suits your requirements.

4. Environmental Factors: Take into account the operating environment, including temperature, moisture, and exposure to dust or corrosive substances, to select a gearbox with suitable protection and durability features.

5. Maintenance and Durability: Assess the ease of maintenance and the gearbox’s overall durability to ensure long-lasting performance with minimal downtime.

Conclusion

In conclusion, the Pto gearbox is a vital component in various industries, offering exceptional performance characteristics, versatility, and reliable power transmission. Understanding the types, materials, and applications of Pto gearboxes enables informed decision-making for optimal equipment performance. With future development trends and opportunities, the Pto gearbox market holds exciting prospects for innovation and growth. Remember to consider load requirements, ratio selection, gearbox type, environmental factors, maintenance, and durability when selecting a suitable Pto gearbox for your specific needs.

Author: Dream