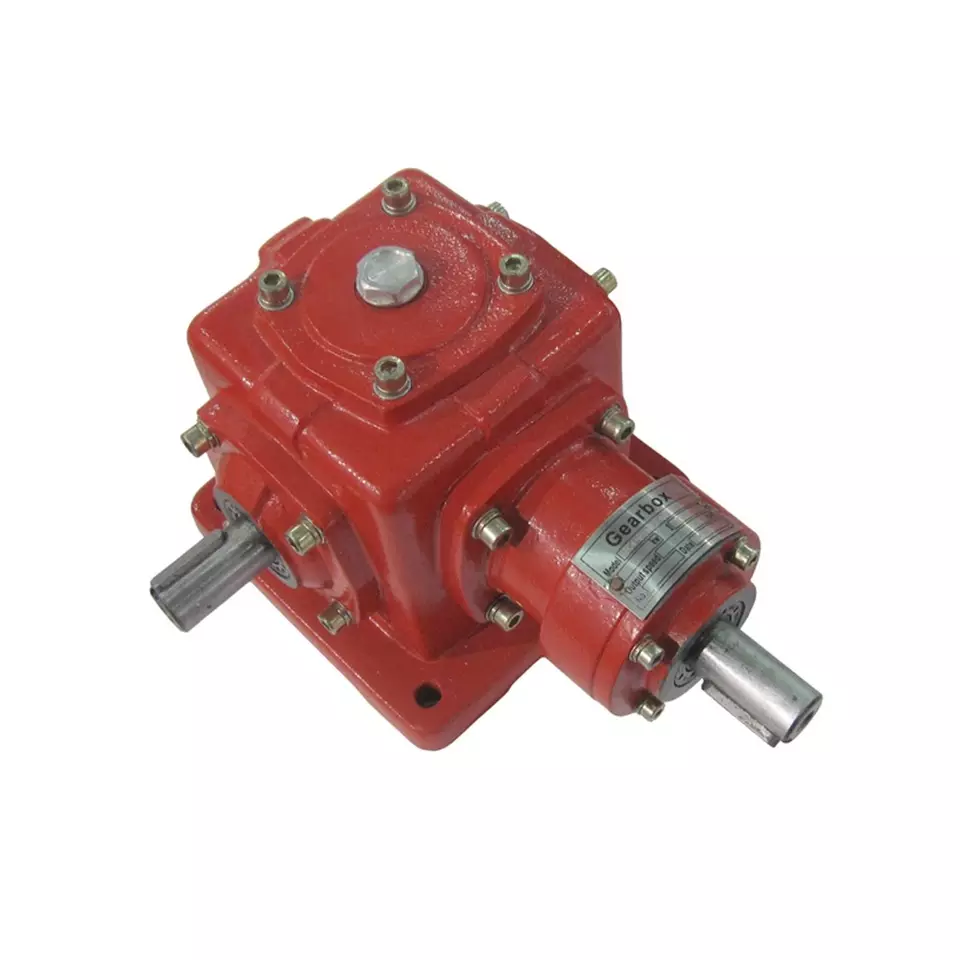

T series Agriculture Gearbox Agriculture Machinery Gearbox

As one of leading shaft clamp manufacturers, suppliers and exporters of mechanical products, We offer shaft clamp and many other products.

Please contact us for details.

Mail:[email protected]

Manufacturer supplier exporter of shaft clamp

T series modular belt sprockets motor gear quadcopter rpm reduction gearbox water turbine gear motor for lifting appliance jack

Advantage:

-Self-locking ability

-Can be driven directly by motor or other power or manual

-Can be customized according user’s demand

-Compact configuration, small size, lightweight

-Convenient installation, flexible operation

-High reliability and stability

-Long service life

-More connection form etc.

Screw jak is applied to all fields for lifting or pulling, such as Aircraft maintenance platform, Solar plate, machinery, metallurgy, water conservancy, medical treatment, chemical industry, culture and hygienist etc.

Specifications:

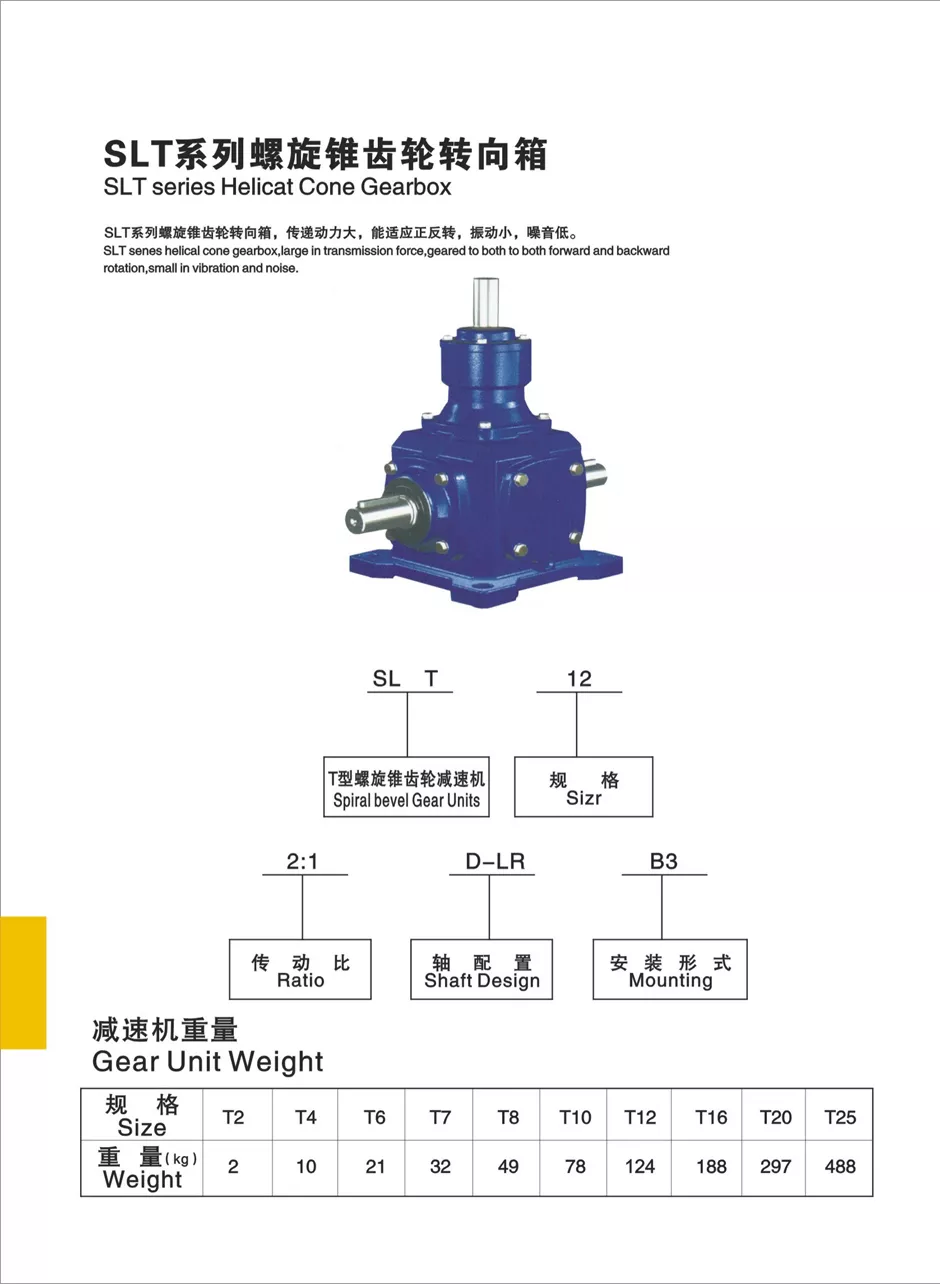

1.Tseries sprial bevel gear reducer with various types are standardized

2.all ratio of 1:1,1.5:1;2:1;2.5:1;3:1;4:1;and 5:1 are actual ones,

3.average efficiency is 98%.

| Product Name | T series Spiral Bevel Gearbox |

| model no. | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25 |

| Ratio | 1:1, 1.5:1, 2:1, 2.5:1,3:1,4:1,5:1 |

| gear Material | high grade synthetic diamond 50CrMnT |

| Gear Processing | Grinding finish by HOFLER Grinding Machines, Precision grade : DIN 4 |

| spindle | high purity steel alloy 40Cr piece |

| Noise Test | Bellow 65dB |

| Warranty | 1 year |

Features

Industry-standard mounting dimensions

Thread-in mounting style

Best-in-class backlash

Four gear ratios available (5:1, 10:1, 15:1, 25:1)

Mounting hardware is roofed for attaching to SureServo motors

Right-angle reducer utilizes a spiral bevel gear; motor could be located at a 90 deg. position from the reducer, providing a more compact footprint

Helical-cut planetary gears for calm procedure and reduced vibration

Uncaged needle roller bearings for high rigidity and torque

Adapter bushing connection for basic and effective attachment to many servo motors

High-viscosity, anti-separation grease will not migrate from the gears; no leakage through the seal

Maintenance free: you don’t need to replace the grease for the life of the unit

At nominal speed, service life is definitely 20,000 hours

Can be positioned in any orientation

5-year warranty

Gearboxes

The gearbox is the principal mechanical component of the kinematic chain of agricultural machines. It is normally pushed by the tractor electrical power get-off through the PTO shaft and the gearbox drives. The running torque can also be transmitted to the gearbox by hydraulic motors or belt pulleys, in addition to chain gears.

Gearboxes constantly have 1 enter shaft and at the very least a single output shaft. If these shafts are positioned at 90° to every single other, the gearbox is an ORTHOGONAL ANGLE gearbox or a lot more typically called a appropriate-angle gearbox.

Agricultural gearbox te chnical requirements

1. There must be no mechanical damage or casting defects such as cracks and holes in any part of the agricultural gearbox.

2. The surface of the gearbox of the machine tool should be kept clean, and the surface finish of the shaft should not be lower than 76.

3. The ellipticity of each shaft hole of the agricultural machinery gearbox is not greater than 0.015-0.02mm.

4. The irregularity of the center line of each shaft hole is not more than 0.04mm, and the length is 100mm.

5. Wheelbase of agricultural machinery gearbox.

6. The relationship between the bearing hole and the bearing seat of the agricultural gearbox.